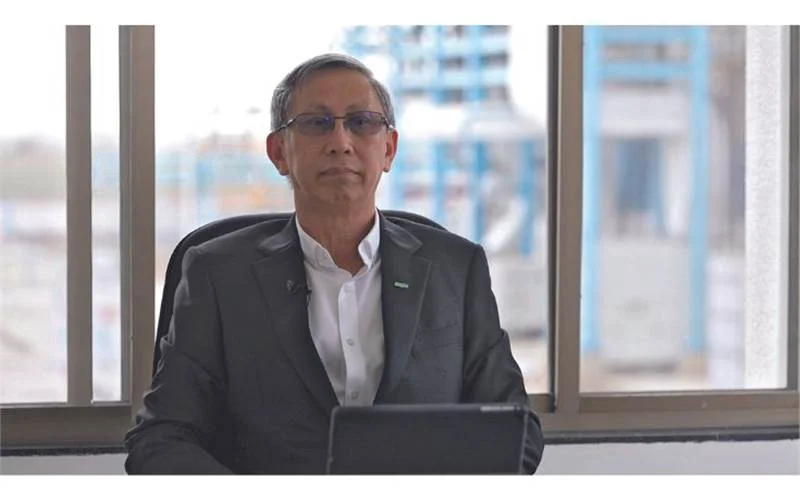

How Manish Bhatia is driving DIC India’s sustainability push

Sustainability and innovation now drive global manufacturing, and DIC India is leading this responsible transformation.

Sustainability and innovation now drive global manufacturing, and DIC India is leading this responsible transformation.

Sustainability, innovation, and responsible manufacturing have become defining priorities for the global printing and packaging industry. As companies navigate rising consumer expectations and stricter environmental regulations, the need for cleaner technologies and future-ready production models has never been more important.

In India, this shift is especially significant, with manufacturers increasingly investing in renewable energy, safer chemistries, and digital-led efficiency. Among the organisations leading this transformation is DIC India, a major player in printing inks and coatings, known for its commitment to sustainable growth and advanced material science.

At the centre of this progress is Manish Bhatia, Managing Director & CEO, DIC India Limited, who has been steering the company towards a future where innovation and responsibility go hand in hand. In this conversation, he shares his insights on how DIC India is integrating sustainability into its operations, redefining product development, empowering talent, and preparing for the next phase of India’s manufacturing evolution.

The Optima plant in Saykha has been recognised as a benchmark for sustainable ink production. How does this facility reflect DIC India’s approach to responsible innovation?

At DIC India, sustainability isn’t a department – it’s an organisational philosophy aligned with DIC Corporation’s Vision 2030. The journey started with Noida plant 2 years ago with moving to solar as the first step, which was then extended to Bangalore with Wind, reinforcing our commitment towards sustainability.

The Optima Plant at Saykha embodies that belief. It was designed from the ground up to minimise environmental impact while maximising efficiency and safety. Every system – from solvent recovery to energy optimisation – reflects our commitment to responsible innovation. What makes Saykha remarkable is that it’s not just a production facility; it’s a living example of how Indian manufacturing can be both world-class and environmentally conscious.

How are customers and partners responding to the growing demand for eco-friendly, toluene-free inks and coatings in India?

The shift is both real and encouraging. Increasingly, our customers are making sustainability a boardroom priority. Toluene-free and low-VOC inks have moved from being niche requirements to business imperatives. What’s particularly heartening is that brands now evaluate supply partners not only on cost and performance but also on shared values. Our role has been to make this transition seamless, to demonstrate that eco-friendly inks can perform as well as, if not better than, traditional systems.

How can India’s manufacturing ecosystem accelerate its transition towards sustainable production practices without compromising competitiveness?

We must stop viewing sustainability and competitiveness as opposing forces. In reality, efficiency and responsibility often go hand in hand. The key lies in investing in technology, skill-building, and process redesign and not merely compliance. If sustainability is embedded into the DNA of operations, from energy use to material sourcing, it becomes a driver of both efficiency and reputation. India has the talent and scale to lead the global green manufacturing story – what we need is deeper collaboration across industry and policy.

How are you redefining R&D and product development to meet evolving sustainability and performance standards?

Our R&D philosophy has evolved from focusing on “better products” to focusing on “better impact.” We’re investing in material science that allows us to reimagine performance through a sustainability lens. The focus now is on lifecycle thinking – understanding how inks perform on press, during use, and at end-of-life. We’ve built cross-functional teams that co-create solutions with customers. That’s how innovation becomes truly future-ready.

What role does digitalisation play in enabling process efficiency, product traceability, and reduced environmental footprint?

Digitalisation is the quiet enabler behind most of our efficiency gains. Data analytics and automation reduce waste, optimise formulations, and enhance consistency. The ability to track product performance and environmental impact provides insights that were simply not possible before. Digitalisation isn’t about replacing people; it’s about empowering them with better information to make smarter, faster decisions.

How do you foster a culture of continuous improvement and creative problem-solving within your organisation?

It begins with curiosity and ownership. We encourage our teams to ask “why” and “what if.” Internal platforms allow employees to share Kaizen ideas – from shop-floor improvements to sustainability initiatives. Recognition plays a vital role. When people see their ideas implemented, it creates a ripple effect of engagement and pride. Continuous improvement isn’t just about margins; it’s about building a culture that’s alive and evolving.

The manufacturing sector is evolving rapidly, driven by technology, regulation, and consumer awareness. How is DIC India preparing its people and processes to stay ahead of this transformation?

Change is constant and the only way to stay ahead is to stay adaptable. We’re investing heavily in upskilling our workforce and redesigning processes to be more agile and data driven. At the leadership level, the focus is on future-proofing – anticipating shifts in technology and consumer behaviour before they become mainstream. It’s about being proactive, not reactive.

What initiatives has the company taken to nurture talent, encourage diversity, and build leadership that can drive sustainable growth?

Sustainability begins with people. We’re committed to creating an inclusive environment where ideas can thrive, regardless of background or title. Diversity isn’t a checkbox for us, rather it’s an enabler of better thinking. Initiatives such as , Shabash DICLeadership Connect, and cross-functional projects provide platforms for recognition, learning, and growth. A culture of empathy and empowerment is what sustains long-term success.

How important is cross-industry collaboration in creating resilient and adaptive manufacturing ecosystems?

Cross-industry collaboration is essential. No single organisation can solve the challenges of sustainability alone. Working with customers, suppliers, and partners helps us share learnings and accelerate innovation. Real value emerges when the entire ecosystem moves forward together.

How do you see the balance between innovation, cost efficiency, and sustainability shaping the next phase of manufacturing in India? How can Indian manufacturers collectively position themselves as global leaders in green manufacturing?

India is at an inflection point. The next decade will be defined by our ability to innovate sustainably while staying cost competitive. The balance lies in long-term thinking and investing in technologies and processes that may have upfront costs but deliver lasting efficiency and brand value. Indian manufacturers can lead globally by proving that scale and sustainability can coexist.

With increasing pressure on industries to decarbonise, how is DIC India working to reduce its environmental footprint across the value chain?

Our decarbonisation journey begins at the design stage – exploring efficient formulations and circular approaches. Across plants, we’re improving energy efficiency, adopting cleaner fuels, and investing in renewables. But it goes beyond operations; we’re engaging suppliers and customers in shared sustainability goals. Reducing our footprint is a collective effort, one we take very seriously.

What emerging technologies or materials do you believe will define the future of inks, coatings, and packaging sustainability?

We see immense promise in bio-based polymers, water-based systems, and functional additives that enhance recyclability. Hybrid chemistries that balance performance with biodegradability are advancing rapidly. The future belongs to smart materials – those that perform better, last longer, and leave a lighter footprint.

How do you see the role of leadership evolving in driving not just profitability but also purpose and societal value?

Leadership today is about balancing vision with empathy, growth with responsibility. A modern leader must build trust and create value that extends beyond shareholders to communities and the planet. Profitability is important, but it must coexist with purpose. At DIC India, our leadership philosophy is simple: do what’s right, even when it’s not easy. Because in the long run, purpose-driven businesses are the ones that truly endure.

Read the original article here: How Manish Bhatia is driving DIC India’s sustainability push