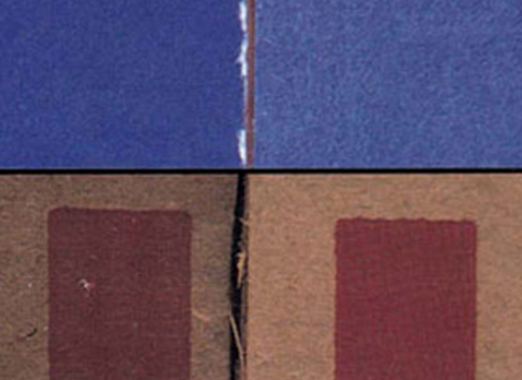

Cylinder rolling is incorrect

Check cylinder dressing, plate inking rollers & blankets if they are swollen

Incorrect dampening solution composition

Its suggested to maintain the alcohol content between -7.5 & -8%

Incorrect ink tack leading to splitting

Adjust the ink tack to avoid splitting

Incorrect plate exposure

Consider changing the plate for better exposure

Ink absorbing too much water

Adjust ink to water balance for better results

Ink build up

Consider reducing the water in the mixture

Ink feed too high

Check density to maintain proper ink feed

Curing is poor

Check the UV exposure, lamp hours for better curing.d

Printing pressure too high

Max recommended pressure is 1N/10mm, keep in within this range

For more information, please contact us.