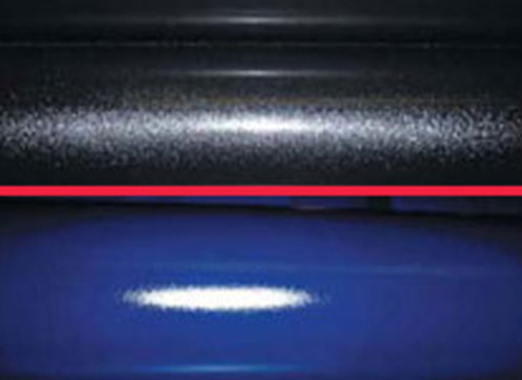

Faulty spray setting - insufficient spray being carried. Uneven coverage of spray

Check sheet under a Lansco light(grazing light). Check your amount of and uniformity of coverage. Correct spray unit if necessary

Ink sets too slowly on paper.

Use a hot air blower too speed up setting. Consult your DIC representative

Lifts stacked too high.

Reduce size of lifts or increase spray, Run sheets into trays

Paper is too hard and solvent penetration is too slow.

Increase amount of spray powder

Rough handling of printed stock or sheets. Poor jogger settings

Handle printed paper stock carefully; reset Jogger so that sheets do not slide

Too much ink is carried

Change to a stronger ink and/or consult your DIC representative,

For more information, please contact us.