Gum arabic and gum substitutes are in fountain solution; wetting agents used indiscriminately

Control use of additives and use proven fountain solution

Ink is unstable

Consult your DIC representative for further instructions

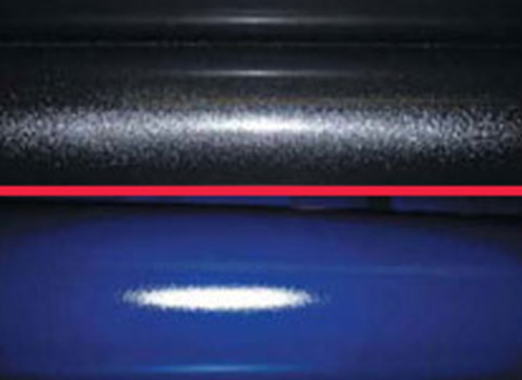

Roller surfaces have calcium build-up on them

Consult your DIC representative for further instructions

Rollers are improperly or inadequately cleaned

Thoroughly clean-up with a good quality roller glaze remover. (To remove glaze apply hot water to roll-ers after removing ink. This will remove gum glaze that is not soluble in standard wash-up solvents)

Rollers are improperly set; rollers are swollen or distorted

Check and adjust roller settings. Check roller surface conditions

For more information, please contact us.