Ink / Water setting is out of balance.

Adjust setting for better results

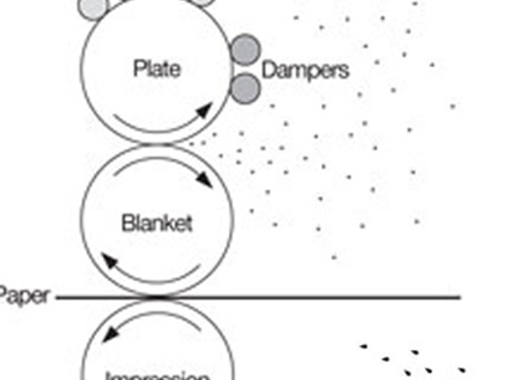

Ink " globs " are being thrown onto the substrates

Adjust Ink/Water balance. Use solid bar (Ink eater ) to +consume the excess ink.

The press temperature is very high.

Check the cooling system for the rollers, Check the fountain solution (IPA, Temperature)

The roller train is affected by static electricity

Check to insure press is properly grounded.

The roller train is too hot

Form roller temperatures should be 72-80"F (22"-26*C). Higher temperatures will lower the tack and viscosity of the ink, lower temperatures will increase the body of the ink

Rollers are worn or improperly set

Check rollers for damage: also check roller settings(check for the extreme temperature build-up on the rollers).

Too much ink is being carried in an effort to achieve the desired density.

Substitute a suitable ink and consult DIC representative

Viscosity of the ink is too low.

Consult your DIC representative for proper solution

For more information, please contact us.