Automatic dosing systems are faulty

Check to make sure that doser is dispensing desired levels of chemistry (perform a "jug test").

Fountain solution circulation system is contaminated

Drain, clean, flush, replace filters and refill with fresh fountain solution. Desensitize rollers

Fountain solution mix is improper

Check PH, conductivity, Brix level and temperature. Ensure pan temperature is not higher than 65.F (18.C)

Inappropriate solvents/washes used to clean metering rollers

Be sure to use metering roller cleaner (MRC)

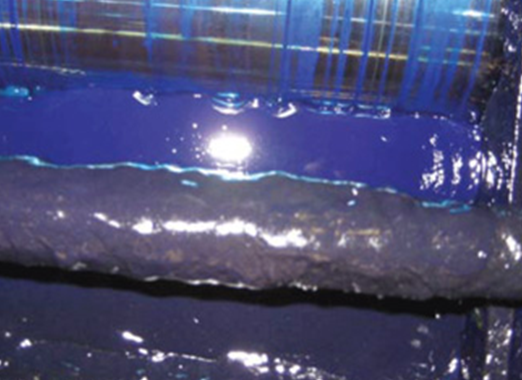

Pan roller is greasy or contaminated

Clean and desensitize the chrome roller with a good chrome roller cleaner and follow up with a hot water / white vinegar (2:1) wash-up

Roller durometer is wrong

Replace the rollers with recommended durometer and check again

Rollers are set improperly

Check settings and the skew of the metering roller and reset to manufacturer specifications

For more information, please contact us.