Dampening water condition is poor.

Clean dampening tank & adjust pH, Conductivity as per standard.

Desensitized metal rollers

Clean or re-copperize rollers for better operation

Duct roller to Knurling roller setting gap too tight or knurling damaged

Please change the roller & adjust pressure to set proper gap

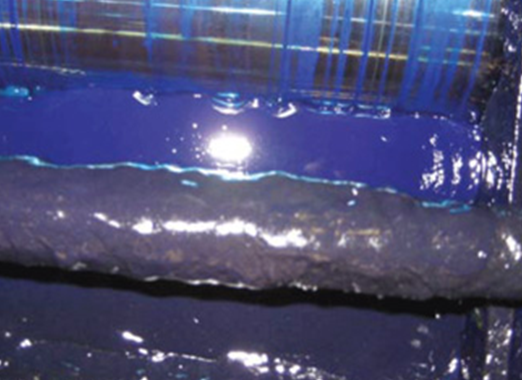

Excess water in the Press

Ink/water balance to be checked and maintained, also check the damp setting

Fountain solution too much acidic

PH to be controlled and maintained from 4.8 to 5.2

Ink - Water curve not adjusted properly

Adjust Ink Water curve with current ink

Ink Roller glazed & hard , so repels ink

Deglaze the rollers with a good deglazer. Check Ink roller Hardness if it is above 40 deg replace the same with new one.

Ink too resistant to water

Consult your DIC representative for further instructions

For more information, please contact us.