Air hitting plates or anilox roll is excessive

Block stray air, balance dryers to eliminame blown down on plates

Dust or ink is picked up from substrate

Check to be sure ink filters are working, filter in to get rid of substrate

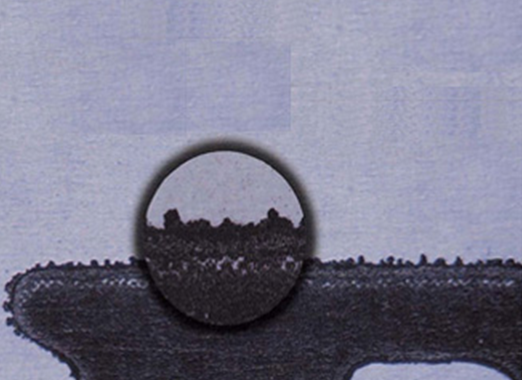

Impression between plate and substrate is excessive

Reset plate pressure to 'kiss' impression

Ink formula out-of-balance, affects film splitting I transfer

Check solvent blends for Alcohol | Ester balance. For clean printing, the resin structures must have the correct solvents.

Ink is drying too fast

Check ink formulation, add slower drying solvents

Ink viscosities uncontrolled. Wring viscosity cups(out of range) for viscosities run. Cups need cleaning and calibrating

Record and control press side viscosities. Check cups for accuracy and selection.

For more information, please contact us.