SunColorBox: Instant Colour Management for Today & Future

The digital revamping over the past 3 decades has completely changed human and business communication. Consistent branding across channels is one way how people communicate with brands. And a key aspect of brand identity is colour.

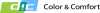

Business packaging and branding involve ensuring consistent colors across substrates, print processes, and national frontiers. If the color isn’t precise, it only ends up compromising the integrity of the entire supply chain and reducing the brand impact.

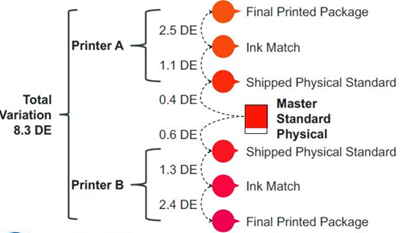

However, effective color management is often impacted because of the inclusion of various parties in color production and approval. Besides, a number of variables, such as package type, substrate, or ink, can make it difficult to achieve true color consistency.

The level of color management continues to vary hugely between converters, even to the point that, in some cases, color on the press is still evaluated by sight alone. The adoption of the latest system is obvious in the field of color management.

Sun Chemical, overseeing DIC group operations in Europe and America and one of the world’s leading printing ink manufacturers, has developed SunColorBox, an end-to-end digital colour management solution to bring consistency in brand colours across the supply chain.

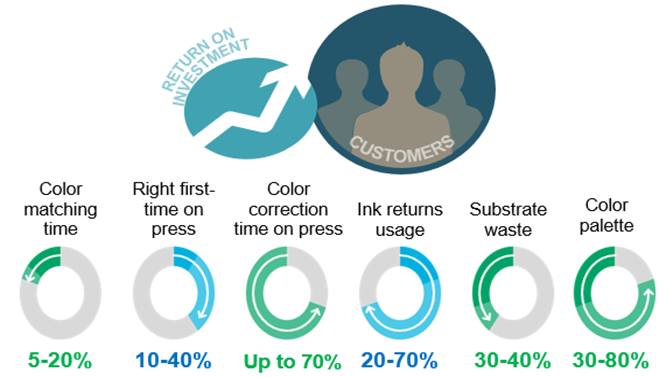

SunColorBox (SCB) is an instant solution for colour, especially for converters and Brand Owners. It is a unique set of tools and services that enables consistent and accurate digital color communication throughout the entire packaging supply chain. The applications and services are aimed at supporting packaging printers and converters to produce brand colors consistently, anywhere in the world, within a fully optimized digital process.

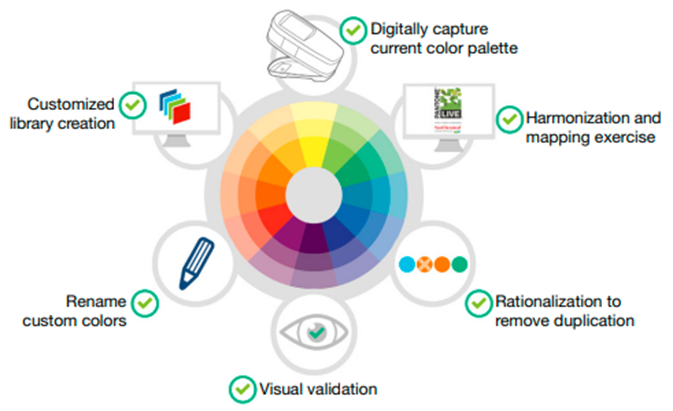

To start the journey toward a complete, digital color management workflow and away from working with a physical color standard, a SunColorBox specialist will digitize the existing spot color portfolio using a spectrophotometer under very controlled conditions so that there’s no variation or inconsistency in the process.

Since 2014, Sun Chemical has been implementing the SunColorBox solution at more than 250 customer’s sites around the world using all printing technologies, including flexo, gravure, offset, narrow web and metal deco.

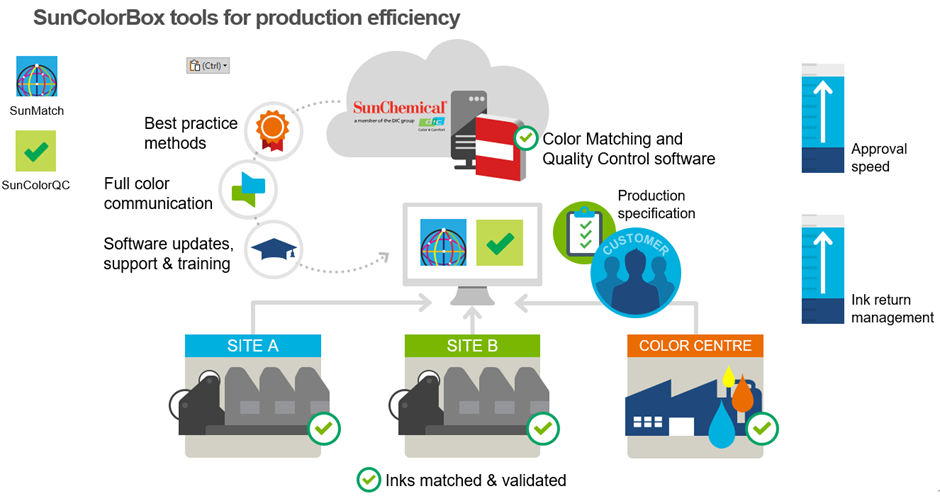

SunColorBox connects multiple customer sites, allowing them to work from the same central data hosted in a web platform.

Hosting a customer room on the DIC / Sun Chemical platform with the customer’s digital palette and specific conditions.

It includes the SunMatch platform, software for Ink Formulation and Color QC.

It is license-based; exclusive login ID/PW will be provided without accessibility of the service provider.

Automatic Software upgrade, all kinds of support and training included

Avoid repeatability or creating duplicate or very similar shades by finding the colour from a customized palette and reducing inventory as well as time.

Use up facility of leftover / Press return ink in new /existing shade

Batch color quality can be checked by SunColorQC. All batch record is stored & the data may be used for leftover facility.

SunConsulting: Color management project setup and color standardization

- First, understand the status of the existing color management workflow. To do that, an exhaustive site assessment is to be carried out.

- The second step is to digitize all approved colors available in the palette to get them harmonized to PantoneLIVE and rationalized to remove duplicates.

SunMatch: Web-enabled, Color Matching Validating platform

- Access to a best-in-class, color-matching software with consistently accurate ink formulation capability, which is hosted on the Sun Chemical network, without investing in the full suite

- Avoid repeatability or creating duplicate or very similar shades by finding the colour from a customized palette and reduce inventory as well as time.

- Implemented using exclusive and best in class Processes and Procedures

- Physical M/S can be avoided

- Use up facility of leftover / Press return ink in new /existing shade

- Avoid human skill dependency.

SunColorQC: Quality Control platform

- Quicker and more consistent batch quality can be maintained.

- Implant confidence to brand owner customers vendor invests in their relationship by adopting technology that will minimize the risk of delivering incorrectly printed packaging.

- No need to keep Physical M/S & skip to change M/S at regular intervals.

- All batch record is stored & the data may be used directly for the leftover facility.

- Entry-level Color QC solution is available with SunConnect for water-based flexo inks.

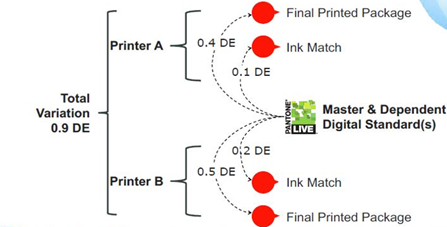

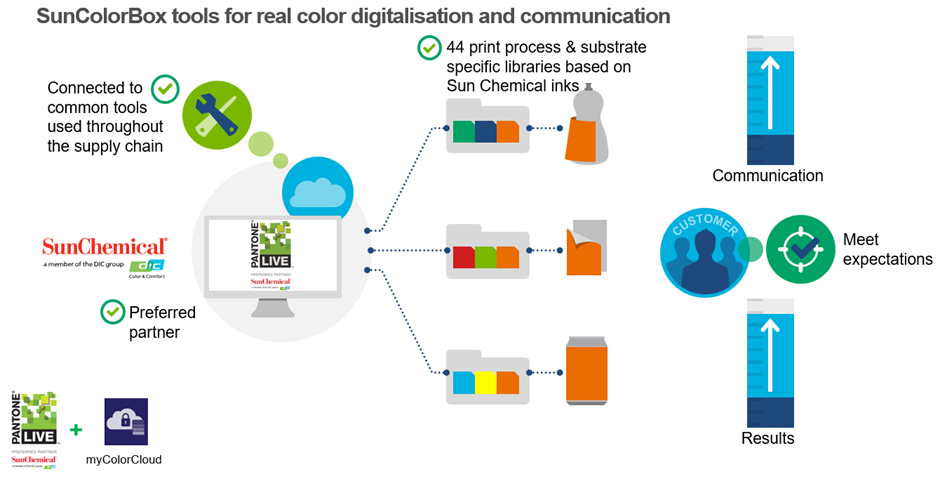

PantoneLIVE™: A Cloud-Based Architecture Enabling Digital Specification and Communication of Pantone Standards

- Master Standard: The ideal representation of a brand color

- Dependent Standard: Closest achievable representation of the Master Standard with a defined, accepted & controlled color shift based on real production substrates and printing technology

- PantoneLIVE Dependent libraries cover 80% of the application technologies in the market today.

- More than 44 Dependent libraries are based on Sun Chemical ink on different substrates.

- Brand Owner specific libraries are built on demand

- Color data from real ink on real substrate

myColorCloud: bespoke color repository

- Supported by the PantoneLIVE infrastructure

- Gives the possibility to share the Brand Owner/Converter palette of colors across the full workflow from design to press

- Color Data are encrypted

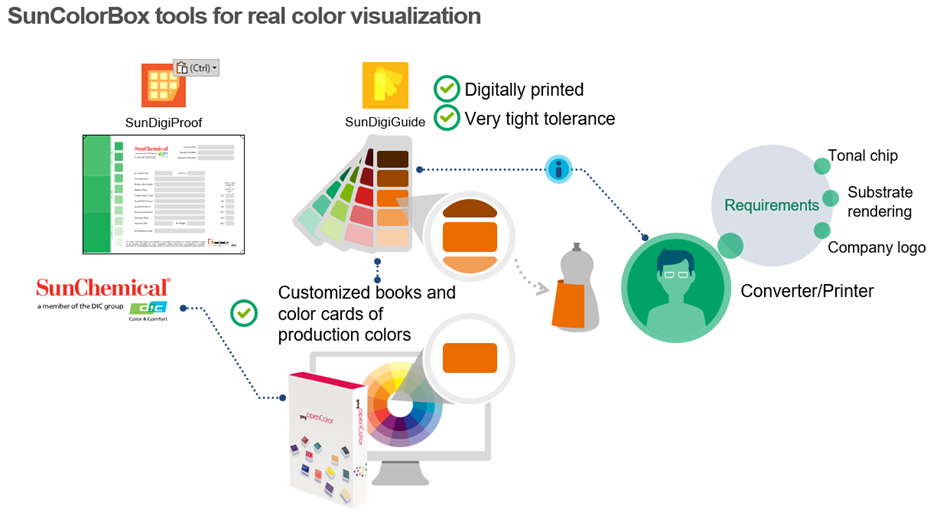

SunDigiGuide: A Digitally printed book of an individual customer’s production colour palette

SunDigiProof: Colour-accurate inkjet Swatches printed onsite and on demand

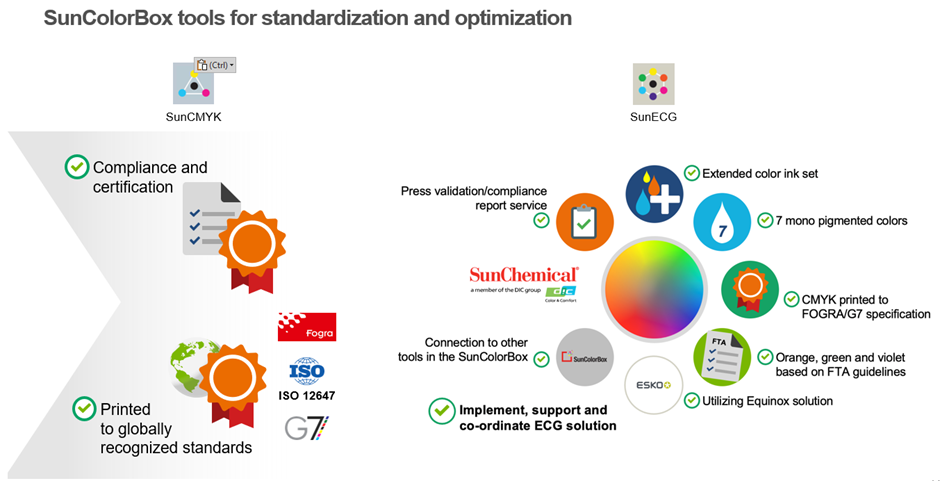

SunCMYK: Consultancy and support to standardize the 4-process color printing system

SunECG: Consultancy and support to implement 7 colors printing system (CMYK+OGV)

Colour Support: DIC India Limited helps to standardize brand colors, color training software SOP, a color audit, an ink dispenser consultation, a process calibration, or any help rationalizing or harmonizing colors.

DIC India first introduced the cloud-based Ink-matching Software toolbox SCB in the nation’s packaging industry in 2020. DIC India has prepared their own base colour database for Offset, Gravure, & Flexo in the lab & validated it at their own ink kitchen. After the successful validation, it was introduced in the Offset packaging market in Q4 2022.

DIC India Limited has established Sun Color Box at 4 customers’ IMC with full package & technical support. The package deal consists of Hardware, Software, Unique SCB ID & other small matching equipment without any extra cost. Full technical assistance is provided at transition time and onwards. Shortly it will be introduced in Flexo & Gravure IMC.

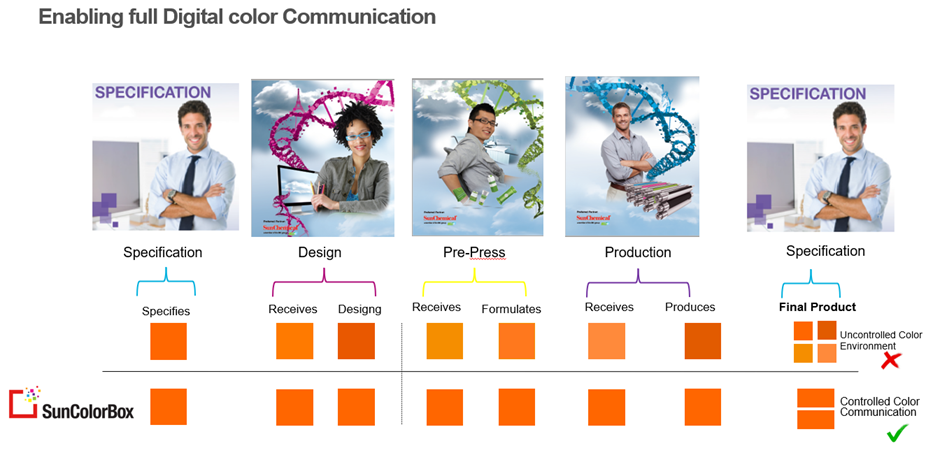

Achieving consistency in color across the supply chain and ensuring effective color management can be difficult to achieve without the support of the latest technology. Sun Chemical’s SunColorBox is a one-of-a-kind solution that lets brands achieve colour consistency across the converters and printers they work with.

The set of unique tools and services with SunColorBox offers accurate color matching, standardizes brand colors, helps achieve color quality, tracks data, and brings a range of support services to ensure seamless color management. Visit the website to know more.