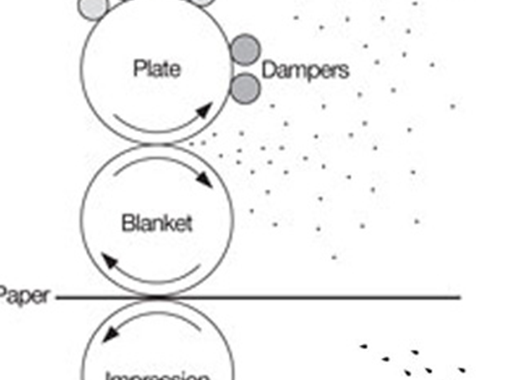

Ink flow is in higher side

Adjust flow to minimize misting

Ink tack is too low

To consult ink manufacturer for next steps

Ink/Water setting is out of balance

Print with minimum water & ink, excess ink/water may create more misting

The Press Room has low humidity

Increase the humidity ( Standard 55% RH)

The Roller train is too hot

Maintain roller temperature within 35 (Max) Deg Cent.

The Rollers are worn or improperly set

To change the worn out rollers with new one and also check the roller settings.

Too much ink is being carried in an effort to achieve the desireddestiny

Substitute a stronger ink and run a thinner ink film on rollers.

Utilization of press is maximum (more than optimum)

Product planning according to Machine out put.

For more information, please contact us.